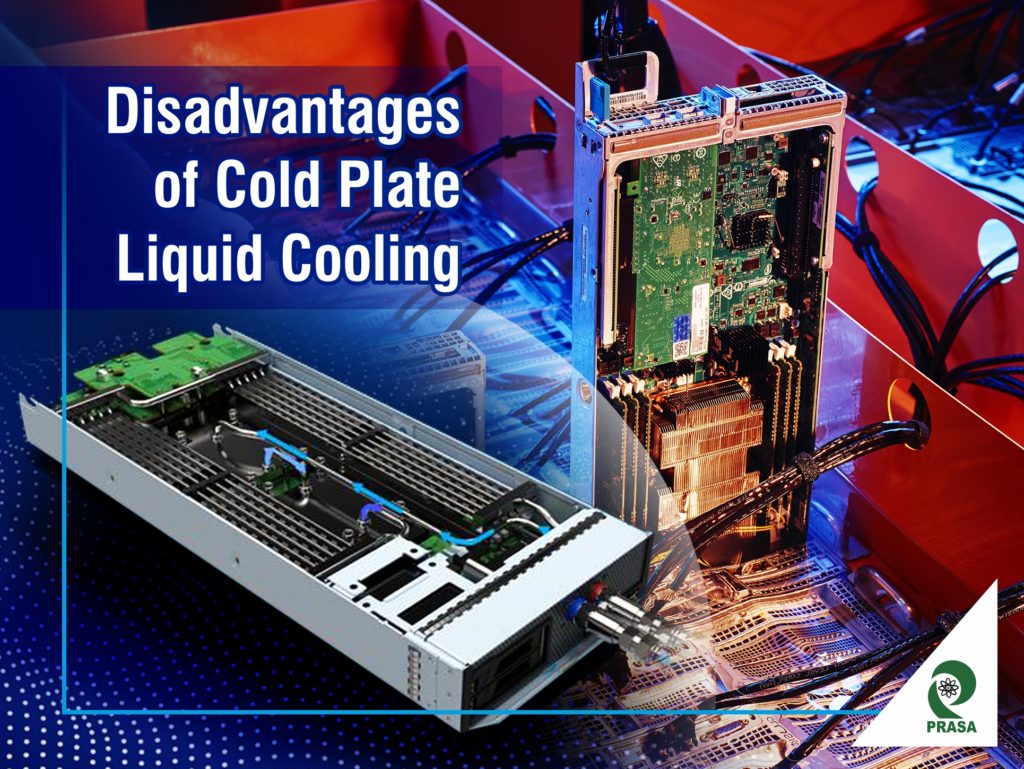

Disadvantages of Cold Plate Liquid Cooling

Cold Plate or Direct-to-chip Liquid Cooling method emerged as an alternative to air cooling and proved itself to be a huge leap forward from the primitive air cooling technologies in the data centers. But as the data centers have grown in capacity and technology in the last decade, this technology has started encountering various problems in this modern data center setup. While it turned out to be a great spot-fix for isolated heating issues, the cost, complexity, and risk associated with cold plate cooling technology have become obstacles to larger-scale adoption in the current situation. There are various more economical options available that deliver superior thermal performance and cooling of servers/components that wouldn’t be feasible with cold plate technology.

In cold plate method of cooling, the chip in the server is cooled by attaching a liquid-cooled metal plate directly on top of the CPU. The coolant is delivered via pipes directly to the cold plate which absorbs heat through a heat-spreading material from chip to the plate. The heated liquid from the cold plate transmits through a coolant distribution unit to the facility water loop which circulates it through a chiller or cooling tower before transmitting the coolant back to the cold plate.

Cold plate or direct-to-chip cooling method can only cool about 60%-70% of the heat load in a data center as it just cools the CPU, for the remaining heat dissipation it usually depends on older and ineffective air cooling methods. Being one of the oldest forms of liquid cooling methods it can be considered among the most popular forms of liquid cooling. Although it has shown better efficiency and performance in comparison to air cooling, its cost, complexity, and potential risks have started giving way to better and more economic solutions like single-phase immersion cooling.

Cold plate liquid cooling served as a stepping stone from air cooling to liquid cooling facilitating and showcasing the advantages of moving away from air-cooled data centers. With time various other innovations in the liquid cooling segment have taken it to another level altogether and surpassed cold plate technology in every possible way. Listed below are the most obvious flaws being experienced with cold plate liquid cooling.

a. Efficiency

The cold plate technology cannot take care of complete cooling needs of the data center and therefore requires dependence on server fans and also chillers, air handlers, and other air conditioning equipment, which increases the OPEX of the facility.

Most modern cold plate systems deliver a PUE somewhere in the neighborhood of 1.15, which is quite high in comparison to other liquid cooling solutions available today.

b. Cooling Liquid

Cold plate liquid cooling uses water or water-glycol mix as the cooling liquid. Water being a good conductor of electricity, needs to be contained within heat sinks and plumbed individually to chips, it is at times physically impossible to fit and plumb multiple cold plates to every CPU and GPU within a high-density server.

c. Capacity

Cold plate cooling technology must theoretically support higher heat influx by using a liquid that offers higher thermal conductivity. But practically this has little to no impact on the power density cold plate can support on a per-server or per-rack basis, which max out at 50 to 60 kW in rack density, making it unsuitable for many next-gen apps and high-density facilities.

d. Reliability

The complexity of cold plate solutions can present significant reliability issues. First, the sheer number of intricate parts and fittings creates numerous failure points. Furthermore, leaks can be catastrophic. The coolant liquid being water here: the enemy of electrical components.

Since server fans are still required, this introduces vibration and poses yet another point of failure. It also exposes IT equipment to environmental assaults (e.g., moisture and airborne particulates), which can hasten deterioration and impact MTBF (Mean Time Between Failures).

e. Flexibility

As for location flexibility, the two things that work against cold plate liquid cooling are the facts that it requires air conditioning infrastructure that is very energy-and cost-inefficient at a smaller scale. It magnifies capital, power, and site constraints. Plus, the fact that components are exposed to air can make these systems a no-go for deployments in harsh environments.

In my multiple posts earlier, I have already established the fact liquid cooling is always a better option than air cooling. But, liquid cooling has evolved significantly from cold plate and we now have the perfected version of liquid immersion cooling, which is turning out to be the latest and the best technology available for data center cooling. In my previous post, I have compared the different generations of cooling technologies in a data center Immersion Cooling and shared the thought process we had when we, at Prasa, decided to bring the technology to India.

Leave a Reply